In today’s manufacturing arena, the importance of quality is a key tenet and plays a holistic role throughout the process. Efficient defect detection is a cornerstone of superior quality.Manufacturing defects can have a significant impact on product quality, customer satisfaction, and overall business success. Detecting and addressing it early in the production process is critical to ensure that only high-quality products reach the market. Traditionally, this task has been performed manually by using measuring tools and checks by workers, resulting in human errors and inefficiencies. However, with advancements in artificial intelligence (AI) technology, manufacturers now have access to powerful tools that can revolutionize processes.

From real-time intervention to unmatched accuracy, AI-based defect detection systems offer a wide range of benefits, including 24/7 watchdog & prediction capabilities, the ability to adapt to any production line, and the capacity to inspect all angles and surfaces.

In this comprehensive blog, we will explore how utilizing AI technology for defect detection can lead to data-driven decisions, improved process efficiency, and automated defect management in manufacturing operations.

Catch Defects Early: The Key to Manufacturing Success

Timely identification of defects helps in maintaining compliance with industry standards and regulations, thus safeguarding the brand reputation.AI technology has the potential to enhance defect detection processes by offering high accuracy and consistency in identifying even the smallest anomalies. With real-time monitoring and predictive capabilities, manufacturers can address defects promptly, leading to improved product quality and reduced wastage.

From Humans to AI: The Efficiency Leap in Defect Detection

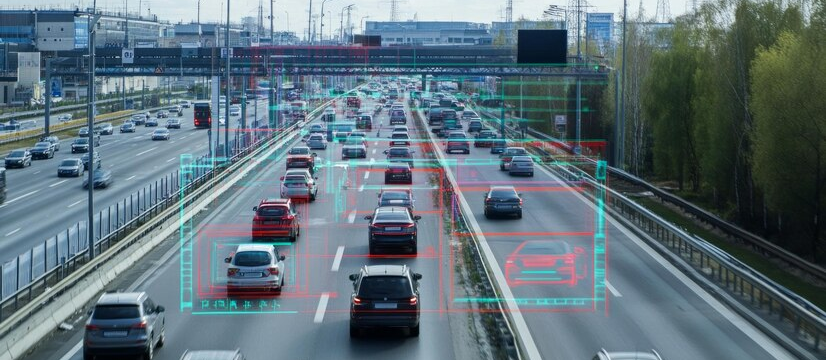

AI technology boosts defect detection efficiency by using advanced algorithms to swiftly and accurately analyze large datasets. Machine learning models spot patterns and anomalies that human inspectors might miss. As production processes grow more complex, traditional manual inspections and outdated equipment can’t keep up with new product standards.AI-enabled systems enhance precision and consistency in defect detection, improving product quality and reducing rejection rates. They also enable predictive maintenance, allowing for proactive issue identification and resolution before they escalate.

AI uses deep learning and smart camera to automatically identify and spot wide range of deformations and surface flaws, thus ensuring high quality. It also identifies and distinguish between critical and non-critical defects accepted by manufacturer’s standards. AI engineers continuously improvise deep neural networks for identifying defects. AI Inspection system distinguish anomalies, characters, & parts similar to human visual inspection in manufacturing.

AI Revolution: Power Up Your Manufacturing Process

To successfully integrate AI technology for defect detection in manufacturing, a strategic approach is essential.

- Identify key areas in your production process prone to defects.

- Determine the specific goals you aim to achieve with AI implementation.

- Collaborate with AI experts to select the most suitable algorithms and models tailored to your manufacturing operations.

- Ensure thorough training of your AI systems with relevant datasets to enhance accuracy and efficiency.

- Regularly monitor and update the AI models to adapt to evolving production environments.

By implementing AI technology thoughtfully and purposefully, you can streamline defect detection processes.

Sharpen Your AI’s Eye: Optimize Defect Detection Algorithms

After identifying key areas and setting goals, the next step is to train and optimize your AI algorithms. Collaborate with data scientists to create high-quality datasets of potential defects. Fine-tune your AI models through rigorous training, and continuously evaluate and optimize them with real-time data feedback. This investment enhances defect detection and boosts operational efficiency.

Computer vision revolutionize assembly line inspection with reduced errors, unmatched speed & precision, and consistent quality control. The algorithm surpassing human capabilities, detect defects at lightening speed and also provided immediate corrective actions.

Real-world Impacts – How AI Unlocked New Levels of Manufacturing Excellence

Many industries have successfully embraced AI technology and the incorporation of AI-powered computer vision technology transcends multiple benefits across a variety of applications. In high-value manufacturing sectors – automotive, medical, aerospace, construction, etc defects can literally prove fatal. Let’s delve into how computer vision technologies make an impact in real-world scenarios.

- Automotive manufacturers: Techniques like edge detection, texture analysis, and color analysis are helpful in identifying defects, and using convolutional neutral networks (CNNs) large datasets of defective and non-defective parts are automatically recognized. Leveraging a combination of computer vision, big data analysis, predictive maintenance, and sensor data analytics, automotive industry enhance quality control and production efficiency.

- Pharmaceutical companies: AI-powered image recognition technology can be utilized to detect minute defects in drug capsules, ensuring highest product quality standards.

- Textile Industries: AI-driven visual inspection systems identify fabric defects and inconsistencies, ensuring high-quality textile products and reducing material waste.

- Food and Beverage Industry: AI-powered vision systems inspect products for defects, contamination, and packaging errors, ensuring safety and quality for consumers.

- Packaging Industry: AI-powered systems check for labelling errors, packaging defects, and seal integrity, ensuring products meet regulatory requirements and brand standards.

- Aerospace Industry: AI technology, coupled with deep learningfind flaws in production process, inspects aircraft components for defects and damage, improving safety and compliance with stringent regulatory standards.

These real-world examples demonstrate the transformative impact AI technology can have on defect detection.

Industry 4.0, the epitome of smart manufacturing, revolutionizes production with real-time decisions, boosted productivity, and unmatched agility. Industry 4.0 technologies are dynamically changing the manufacturing sector as many companies are switching to AI-powered visual inspections, thus cutting manufacturing errors and saving time and money. With minimal investment, quality control staff can use a cloud-connected smartphone to monitor processes remotely. Machine learning algorithms detect errors instantly, avoiding costly late-stage repairs.

Machines with Minds: The Rise of AI-Powered Production

As we move forward, the landscape of AI technology in manufacturing is set to evolve rapidly. Innovations such as machine learning algorithms, advanced neural networks, and deep learning capabilities hold promising potential in enhancing defect detection processes. Integration with IoT devices, AI, real-time data analytics and other connected technologies into everyday factory operations, a new high wave of optimization is observed without any major investments.

EdgeSkope AI, cloud-based next gen AI solution from fastedge.ai aids in efficient defect detection in manufacturing industries and plays a crucial role for enhancing operational efficiency and maintaining a competitive edge. From detecting subtle flaws in textiles to ensuring the sterility of pharmaceuticals, it detect potential equipment issues before they interrupt production. With advancements in machine learning algorithms and real-time data analytics, manufacturers can achieve optimized processes and improved precision in defect detection.

Key takeaways include the importance of early adaptation to AI advancements, integration with IoT devices for streamlined operations, and the potential for increased automation in defect detection processes. By staying informed about the latest trends and developments in AI technology, manufacturers can position themselves to thrive in an evolving industry landscape.

FastEdge.AI, is an edge AI & computer vision company specializedto deliver high efficiency next-gen AI-Powered solutions, with real-time monitoring on audience measurement, object detection, process enhancement, & more. With precise performance metrics, EdgeSkope AI personalizes experiences and unlocks new revenue stream.

Comments are closed