Defect Detection

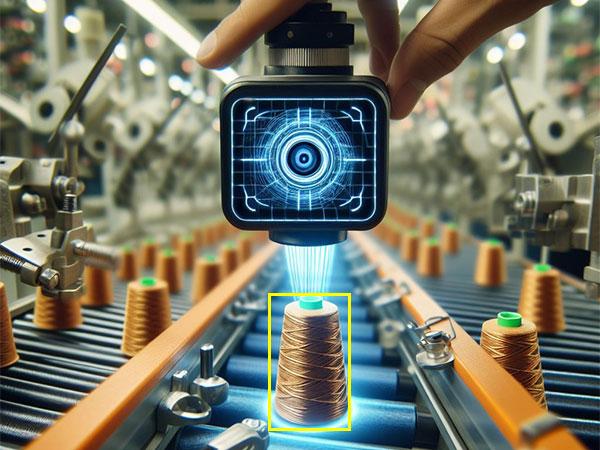

Defect Detection Solutions with EdgeSkope AI

From identifying subtle flaws in textiles to ensuring the sterility of pharmaceuticals, EdgeSkope AI helps you safeguard your production line and deliver exceptional products.

- Fabric & Textile Defect Detection: Identify tears, snags, uneven weaving, color variations, and other defects on various fabrics during production.

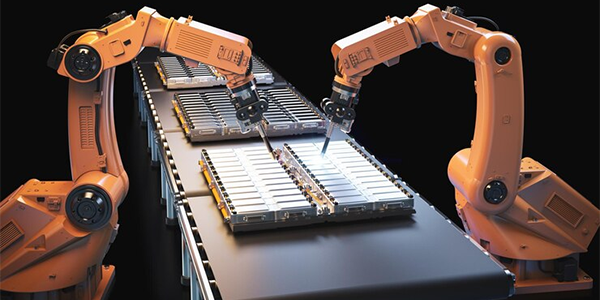

- Electronic Component Inspection: Eliminate manual counting errors.

- Product Finishing & Assembly Line Inspection: Ensure consistent quality in final product finishing, identifying scratches, dents, improper assembly, or mismatched parts on a variety of manufactured goods.

- Food & Beverage Production Inspection: Detect foreign objects, inconsistencies in size or shape, and potential contamination issues in food and beverage production lines.

- Pharmaceutical Manufacturing & Packaging Inspection: Ensure consistent quality and sterility of pharmaceutical products by identifying defects in tablets, capsules, and packaging materials.